Supplying water to a region facing scarcity.

| The challenge

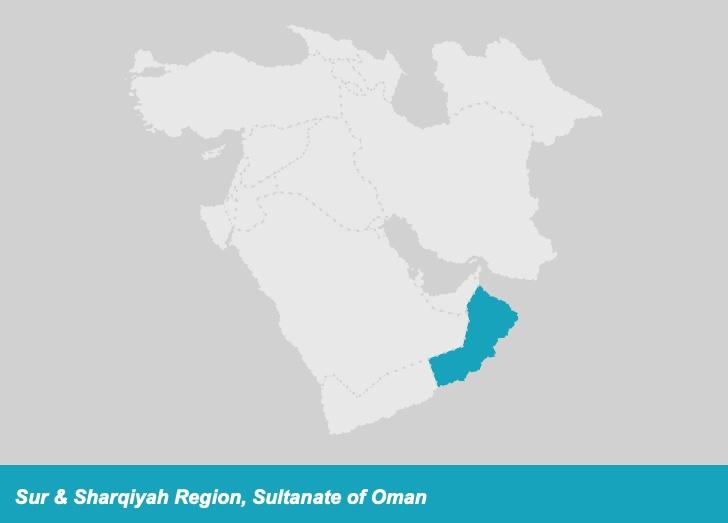

The Sharqiyah region, situated on the eastern coast of the Sultanate of Oman, is suffering water stress all over the year round.

As a result of drought and over-exploitation of underground resources, groundwater has to be protected and spared as much as possible.

Nevertheless, the 600 ,000 inhabitants of the Sharqiyah region have to be daily supplied with drinking water.

Therefore, PAEW (Public Authority for Electricity and Water) has awarded Sharqiyah Desalination Company, a Veolia company, with a contract to build, own and operate the reverse osmosis desalination plant of Sur in 2007.

| Veolia’s solution

The contract awarded covers the construction and operation of a 30 million m3 per year (80,000 m3/day) desalination plant in Sur, and the construction of a reservoir with a capacity of 160,000 m3. Veolia was awarded the expansion of 48,000 m3/d the plant on a BOO base in 2014. The seawater abstraction is presently the largest beach well facility ever built in the world for a desalination process.

The Sur desalination plant complies with the more stringent environmental criteria in order to protect water resources as well as the environment as a whole. The plant implements the membrane desalination process, also called reverse osmosis process. Veolia is therefore delivering high quality drinking water while limiting the impact on the environment.

| The benefits

Efficient operations:

The Sur plant uses an innovative, pioneering and efficient technology with the beachwells, and this is presently the largest beachwell facility ever built in the world for desalination process. The daily 120000 m3/ drinking water produced use reverse osmosis process with very high energy efficiency, recycling over 90% of the mechanical energy and saving up to 40% more energy than a conventional reverse osmosis plant.

The Sur desalination plant therefore combines world class desalination process and technology, with energy efficiency.

Sustainable Development:

Bahwan Veolia (BV), the entity in charge of the O&M of the plant, has developed and implemented a tool to follow up the carbon footprint of its operations on a monthly basis. In order to assess the potential for reducing its carbon footprint, Veolia has carried out feasibility study to evaluate the impact of substituting part of its electricity consumption by the electricity produced by on-site renewable energies technologies. The study helped identify the best solutions among renewable energies according to the weather, operations & maintenance constraints, site location and field. The plant’s unique facility also eliminates the requirement for chemical pre-treatment and ensures minimal impact on the marine and coastal ecology.

Quality Management System:

An integrated management system has been designed and implemented. This system encompasses quality management, environmental management, and occupational health and safety. Several initiatives have been launched as part of continual improvement such as waste segregation, new entry systems to the process buildings to reduce injury risks, use of a e-learning system for H&S training, design and installation of a chemical PPE house. Bahwan Veolia has received in July 2012 the triple certification for its integrated management system compliant with the following standards: ISO 9001:2008, ISO 14001:2004, and OHSAS 18001:2007, being the first plant of Veolia within the GCC region to have such recognition and the only water plant in Oman with such international certification level.

Human Resources:

BV’s management has successfully maintained a very low staff turnover which is critical to capitalize reverse osmosis know-how, to maintain a strong team spirit, and to have experienced talents pulling beginners or unskilled staff.

As part of HR management, several actions have been implemented such as promotion of staff enhancement within the company and improvements of the social conditions and the work environment. For example, a multi-sport complex was implemented by refurbishing and converting the old plant building. It is now available to staff and families, which amount to around 100 people. This project was led by a team of employees. It is now a real success.