What is the climate crisis?

Definition and causes

Climate change, or the climate crisis, refers to observed statistical changes in the earth’s regional and global climate.

People have been talking about climate warming ever since the Industrial Revolution in the 19th century. It is caused by alterations in the make-up of the earth’s atmosphere as a result of human activities, specifically greenhouse gas emissions. We hear a lot of talk about carbon dioxide (CO2), which is responsible for close to 65% of greenhouse effects caused by humans (anthropic), but is not the only cause. Methane (CH4), for instance, is responsible for 17% of anthropic greenhouse effects, according to the Intergovernmental Panel on Climate Change (IPCC).

This clearly shows that the influence of humans and their activities on the climate emergency is beyond any doubt: we emit too much greenhouse gas.

Veolia commits to avoid 18 million tonnes of CO2eq at it's our customers’ sites by 2027.

What are the consequences of the climate emergency?

Published in 2014, the 5th IPCC1 report was very clear: the atmosphere has unarguably been warming since the 1950s. And the consequences, such as rising sea levels, are occurring at an unprecedented pace.

We are already experiencing effects associated with these changes, such as heatwaves, extreme variations in rainfall, greater pressure on biodiversity and storms of ever greater severity.

According to the IPCC2, limiting climate warming to 1.5°C means CO2 emissions must fall 45% by 2030, compared with 2010 levels, and reach net zero by 2050.

How do we help fight the climate crisis?

We innovate and work constantly to reduce or even eliminate greenhouse gas emissions from the entire value chain for all our activities.

Reusing materials emits less CO2 than extracting, producing and transporting new resources. Our priorities include generalizing the shift to a more circular economy, a new model for using resources more sparingly and more effectively. Working to make sure that what is rejected in one place becomes a resource somewhere else.

Discover how we optimize resources >

As well as CO2, we also look very closely at methane emissions, a pollutant with very large warming potential. Our then-CEO Antoine Frérot discussed this issue in New York at the 2014 Climate Summit.

We help every industry cut its emissions

We offer a range of solutions tailored to tackle the challenges and issues facing every sector, including mining, agrifood, pharmaceutical, and automotive.

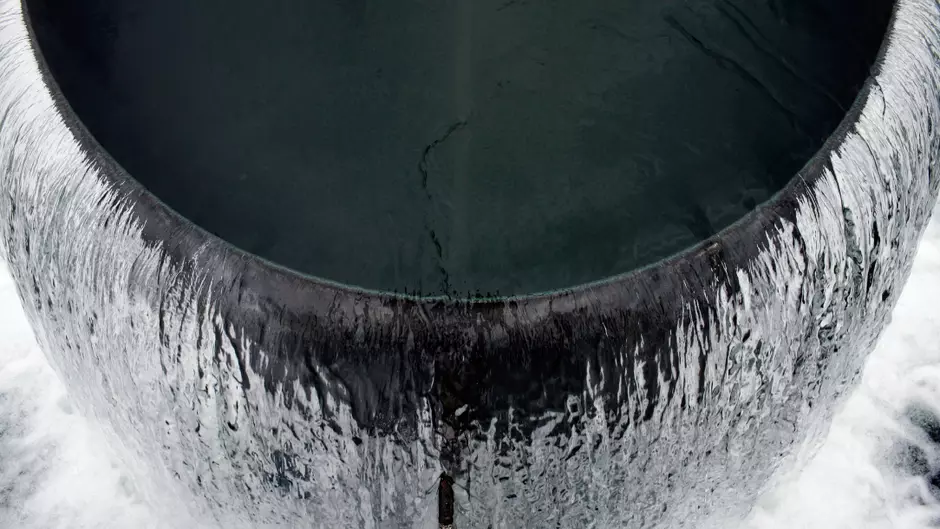

We have developed several families of solutions to improve how resources are managed and shrink carbon footprints. These include energy efficiency and heating networks, producing renewable energy, recycling and recovering materials, waste and water.

We help cities and industries adapt to the climate crisis

We implement solutions such as wastewater reuse to limit pressure on water resources and conflicts surrounding water use, or for avoiding floods by controlling sewage systems during heavy rain. When extreme weather events do occur, we act to manage the crisis or set up plans to ensure continuity of essential services.

Act for ecological transformation

The challenges of ecological transformation

Regenerate Ressources

Faced with the risk of depleting natural resources, we are committed to protecting and renewing them, in particular by using the circular economy model.