The transition to a circular economy has become a necessity. Faced with the limitations of our linear production and consumption model, how can we encourage development of more circular, simpler practices at all levels? To address this, the Veolia Institute held a conference on 23 November at the Group’s headquarters in Aubervilliers and released a new issue of its Facts Reports on the topic: “Industry and waste: towards the circular economy”.

Two centuries ago, waste did not exist. Everything was a resource, and the economy was completely circular. We cannot imitate this circular economy. We must invent a new one. In the past, everything was reused, but recovery was gradually banned for hygienic reasons.

Today, the circular economy is an absolute imperative: over the next four decades, raw material consumption is expected to double. In everything we do, most of our consumption is hidden.

For example, in digital, 90% of energy consumption is spent in the extraction of materials and their transformation into products even before utilisation.

Only 9% of raw materials are recycled in the world (14% in Europe). For rare metals, the recycling rate is barely 1%, and the products that contain them, such as mobile phones, will become real mines.

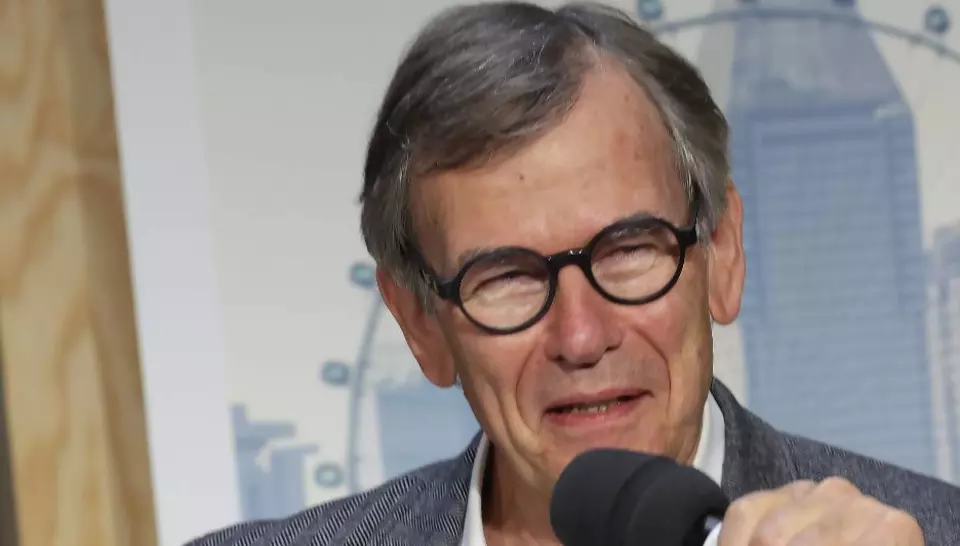

Recycling won’t be enough. For nickel, for example, all of the metal is lost after 3 to 5 recycling operations. The circular economy also includes reuse, repair, and eco-design. These various strategies require new models to be invented. To move towards a strong circularity, traceable and reusable products must be designed. However, there are other challenges such as toxicity, technology, and cost. Governments therefore have a role to play by promoting investments, imposing standards, guiding behaviour, and devising indicators. After labour productivity, we must now focus on a new productivity of natural resources through the circular economy, recalled Nicolas Renard, executive director of the Institute, introducing the debate.

Sobriety, a challenge to our way of life

Valérie Guillard, professor of marketing at Université Paris Dauphine, is interested in consumer behaviour and addresses the issue of sobriety, in particular in the field of consumption of material objects. Upstream of the circular economy, sobriety questions the need that precedes the purchase, the conditions of production of objects, their use, and their repair. It requires the acquisition of knowledge: how an object works must be understood to be able repair it and then recycle it. With sobriety, we challenge our way of life because it involves both “consuming better and less”.

There are four conditions for changing our consumption patterns: knowing, wanting, doing, and being able to do. We first need to take a look at ourselves to become aware of the impacts of our consumption. “Wanting” means making the effort to understand. “Doing” means changing your practices and habits. However, “being able to do” goes through businesses and territorial units. For example, composting requires an easily accessible composting facility.

Product sustainability: a driver of the circular economy

The HOP (Stop Planned Obsolescence) organisation was created in 2015 to inform, influence public decisions, and support companies that are committed to the sustainability of their products. For HOP, there are three forms of planned obsolescence of objects: direct technical obsolescence (containing a part with a short life) or indirect technical obsolescence (because irreparable); aesthetic or psychological obsolescence to encourage the purchase of new products; and software obsolescence, through automatic updates.

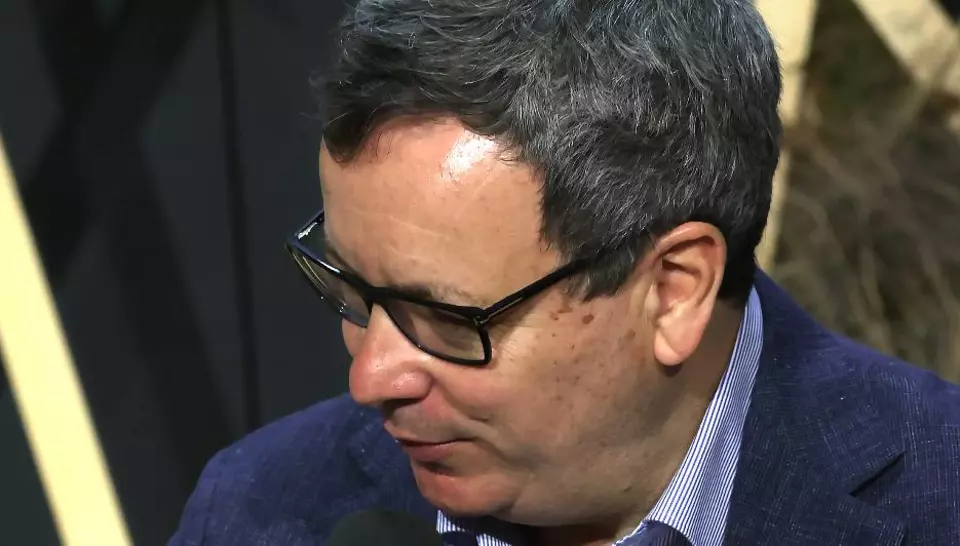

Ronan Groussier, Head of Public Affairs at HOP, explained:

Sustainability, which is at the heart of the circular economy, increasingly desired. In Europe, if we extend the life time of all commonly consumed objects, we can to avoid the equivalent of CO2 emissions from 2 million vehicles in use. HOP participated in the development of the AGEC anti-waste law of February 2020 recommending durability and repairability indicators as well as a fund to support durability. However, we were unable to have a sufficient influence on better supervision of advertising, the software aspect of obsolescence, and the eco-design of products.

The circular economy: creator of back-to-work jobs

Jean-Paul Raillard, chairman of Fédération Envie, recalled that a street educator, a director of Darty, and a manager of Emmaüs joined forces in Strasbourg in 1984 to create the Envie network with the aim of repairing products and selling them with a one-year warranty.

The employment of young people in jobs with environmental value can lead to local revitalisation. The Envie network now has 52 member companies for the repair of large appliances, medical equipment (such as wheelchairs), and WEEE. It employs 2,800 employees, including two thirds in back-to-work jobs, who repair and sell 100,000 devices each year. For Envie, the circular economy creates local jobs.

Recycling: at the centre of the ecological transformation of mobility

Cédric L’Elchat, chief executive officer of Veolia subsidiary SARP Industries, explained why the development of electric vehicles represents a major challenge in terms of public health, climate, environmental protection, and strategic resources. Recycling electric vehicle batteries is a solution for the future.

The source of metals from electric vehicle batteries will be found in all vehicles in use. That’s why recycling is provided for in the regulations governing eco-mobility. Recyclability is now key in the technological competition between battery manufacturers, a challenge to be taken up by recyclers. Beginning in 2030, batteries in Europe will contain a significant proportion of recycled metals such as nickel, cobalt, and lithium. At Veolia, our process includes securing and dismantling batteries. We then use a hydrometallurgical treatment to produce metal salts that are pure enough to be incorporated into new batteries. Recycling is at the centre of the industrial transformation of eco-mobility. To build circular loops of new products, new skills are needed. For example, auto garage employees are becoming high-voltage specialists.

This conference-debate was moderated by Franck Aggeri, professor of management at Mines ParisTech, who coordinated the issue of Fact Reports on the Circular Economy, by the Veolia Institute.

Take a look at the articles from the FACTS Report on “Industry and waste: towards the circular economy”:

- Introduction by Nicolas Renard, Executive Director, Veolia Institute

- Circular economy: strategies and policies – some key figures

1. The need for a new waste management model

From waste to urban mines: a historical perspective on the circular economy

Franck Aggeri, MINES ParisTech

Resource reuse and recycling: limitations and potential opportunities

Thomas Graedel, Yale University

Enhanced landfill mining (ELFM), concept and challenges

Joakim Krook, Linköping University

Extended producer responsibility (EPR) in France

Jacques Vernier, French Extended Producer Responsibility Waste Schemes Commission (REP)

Illegal waste shipment: an overview

Katie Olley, Scottish Environment Protection Agency (SEPA)

Circular Africa: a model for us all?

Alexandre Lemille, ACEN - ACEN, the African Circular Economy Network

2. Shifting how the various actors behave

Towards a society of sobriety: conditions for a change in consumer behavior

Valérie Guillard, University Professor

Accelerating the transition to circular consumption models: the example of the AGEC law in France

Adèle Chasson, Laetitia Vasseur - HOP - Halte à l’Obsolescence Programmée (Stop Planned Obsolescence)

The power of public procurement in the transition to a circular economy

Ashleigh McLennan, ICLEI (International Council for Local Environmental Initiatives)

Birgitte Krebs Schleemann, DGE

Questioning the digital reflex

Xavier Verne, Shift Project

Industrial symbiosis: practices in China’s industrial parks

Zhao Kai, China Association of Circular Economy

Industrial eco-parks as drivers of the circular economy

Franck Aggeri, MINES ParisTech

Measuring circularity at the corporate level

Irene Martinetti, World Business Council for Sustainable Development (WBCSD)

Jarkko Havas, Ellen MacArthur Foundation

Co-development of industrial-quality post consumer recycled plastic: the example of Groupe SEB and Veolia

Ingrid Tams, Jacques Tanquerel (Groupe SEB)

Françoise Weber, François Guéneron (Veolia)

3. Pathways to an innovative circular economy

Recycling electric vehicle batteries: ecological transformation and preserving resources

Pascal Muller, Emeric Malefant, Romain Duboc - Veolia

Repair, reuse and jobcreation

Jean-Paul Raillard, Fédération Envie

Introducing materials from the circular economy into the construction industry

Arnaud Bousquet, Matériaupôle

Using digital to develop the market for refurbished products

Camille Richard, Back Market

Signify, circular lighting to preserve value

Francois Darsy, Signify

Leading a corporate ecological transition: the example of Interface, Inc.

Eric Rampelberg, Interface Inc.