Working via its Chinese joint venture Lijia, Veolia uses its risk prevention expertise to help process hazardous waste created during the epidemic.

Issue

Manage hazardous waste in China during the Covid-19 health crisis, a situation without protocols or precedents, made more complicated by staff shortages at many sites during the Chinese New Year holiday.

Goal

Protect public health and demonstrate Veolia’s ability to adapt and take a lead by disposing of rapidly increasing volumes of hazardous waste in increasingly tight deadlines.

Veolia’s response

Set up a 24-7 service with the specialist skills needed to ensure a clear distinction between medical waste and non-medical waste, and be able to efficiently process a near doubling of volumes.

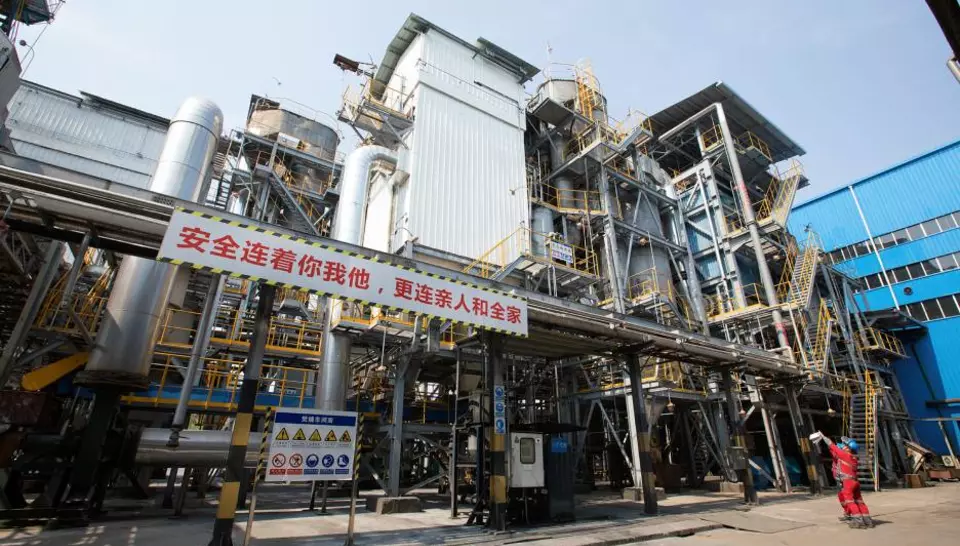

In January 2020 Lijia, located in Hangzhou and one of the largest hazardous waste facilities on China’s eastern seaboard, was preparing for a highly risky undertaking. Covid-19 was spreading rapidly across the country and Wuhan, a city of 11 million and the epicenter of the pandemic, was in total lockdown.

And all this was happening just as the people of China were about to start their celebration of the Lunar New Year. “This is China’s largest annual migration and already a peak time in the waste business,” explains Dai Bing, General Manager at Lijia, a joint venture between Veolia and its Chinese partner. Millions of businesses use this period as an opportunity for an in-depth annual clean up, and many waste processing facilities are also shut down for the holidays.

This combination of circumstances creates an exceptional spike in pollution levels and hazardous waste production. Throughout this period, Lijia continued to operate at full capacity, serving its industrial customers that were unwilling or unable to close down for the two-week holiday. So, when Covid-19 struck central China, Lijia was one of the few plants in the region that was operating at full capacity.

Building trust in the shift to a circular economy

Although recycling was far from the largest preoccupation at the time, Lijia’s response to the crisis was built on Veolia’s circular economy: treating waste as a resource. It set an example for the entire province, giving local authorities actionable guidance on transporting, monitoring and declaring these new contaminated waste streams to avoid any risk of mingling with household waste streams.

In the field, Veolia continued to focus on its risk-prevention culture. At a moment when the whole world was threatened by shortages of personal protective equipment (PPE), there was never any risk of stocks running out at the Hangzhou site.

Pollution: Veolia continued to focus on its risk-prevention culture

The plant began by controlling how PPE was used, then established specific hazardous zones, each with its own protocol. Ultimately, appropriate use of PPE reduced operational risks while preserving critical stocks. And Lijia was even able to help supply PPE to certain government agencies.

Environment: demonstrating adaptability and expertise

A few days after being tasked with its new mission, the amount of waste handled by Lijia had already doubled. This in turn doubled the pre-processing workload and led to a rethink of its incineration methods, as the government demanded all medical waste be processed within 24 hours, instead of 48 hours previously.

Between the Lunar New Year and September 2020, the site disposed of almost 2,000 metric tons of waste from the Hangzhou Medical Observation Center and the province’s quarantine zones, on top of its usual seasonal activity peak. Management, training and Veolia’s technical expertise all played key roles in rolling out new capacity at Lijia.

Between the Lunar New Year and September 2020, the site disposed of almost 2,000 metric tons of hazardous waste.

For Dai Bing, these efforts are testimony to the site’s operational efficiency and the professionalism of its staff. Even with this increased workload, operations remained fully controlled and neither the site’s staff or its operational resources were ever overstretched. “We now know that working like this is viable,” says Dai Bing. “As a franchise operation, levels of waste handled at the plant are set in advance by the government and customers. But now we know that we can exceed the limits if the need arises.”