The electric vehicle market has been growing rapidly for several years. Replacing IC vehicles at high speed, nearly 77 million hybrid and electric cars could be sold by 2025, according to the IAE’s Global EV Outlook 2022.

These numbers are growing and will continue to grow for a long time. Battery recycling is therefore a necessity to limit the pressure on certain metals and to conserve our natural resources.

Why battery recycling is a real environmental issue

EV batteries weigh an average of 300 kg but can be up to twice that for some models.

They are composed of plastics, solvents, electronic compounds and small quantities of high-value metals such as lithium, cobalt, copper, manganese and nickel.

These highly strategic metals are essential to our energy transition. Nevertheless, their extraction and production are concentrated in a few geographical areas. This situation leads to tensions over resources and distribution channels in the face of growing demand. Recovering the metals contained in end-of-life batteries is an ecological solution that mitigates the pressure on virgin raw materials, limits the carbon and environmental footprint associated with mining, and protects the environment from pollution emanating from end-of-life batteries.

European legislators* have taken matters into their own hands with a proposed new regulation making it mandatory to include recycled raw materials in the production of new batteries:

- 2025: mandatory declaration of the percentage of recycled content

- 2031: 16% for cobalt, 6% for lithium and nickel

- 2036: 26% for cobalt, 12% for lithium and 15% for nickel.

European institutions also aim to define how efficient the recycling process is, and therefore the yield from the processes used, with new mandatory targets:

- 2027: 90% for cobalt, copper and nickel, 50% for lithium

- 2031: 95% for cobalt, copper and nickel, 80% for lithium

*Final figures for the regulations adopted by the European Parliament on June 14, 2023.

Our solutions for recycling electric car batteries

Veolia, a long-standing player in the treatment of batteries and accumulators, has unrivalled expertise in all stages of recycling. Our know-how in the management of hazardous waste flows and the associated risks has enabled us to develop specific, high-performance processes.

Our solution for recycling electric car batteries is divided into 5 main stages:

- Collection, securing and fully discharging the battery

- Dismantling each component to be sent to the appropriate sector for recycling

- Mechanical separation to extract the black-mass contained in the cells that make up the battery

- Hydrometallurgy to separate and purify the metals contained in the black-mass

- Refining to bring the metals to a degree of purity so they can be reused to make new batteries

- You benefit from non-negotiable safety requirements

- You gain access to durable, quality recycled electric battery components

- You maximize the performance and costs of your operations

What are the benefits for you as a manufacturer of electric vehicles?

- A permanent commitment to the safety and traceability of our businesses

- The power of an international group with a strong local network

- Collaboration adapted to the specific needs of your business

- Constant focus on inventing tomorrow's solutions

The Veolia difference

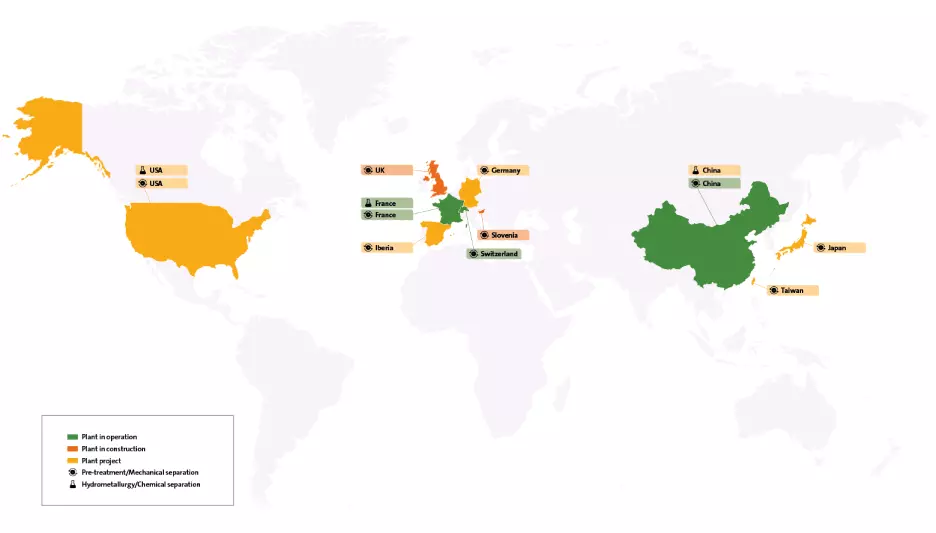

Our locations

We did it!

France

Veolia has teamed up with Renault to work jointly on recycling the batteries of all the electric vehicles sold by the carmaker in Europe. Together we are working to reduce the environmental footprint of mobility, for a more sustainable world.